LOTUS TMT

BDG Metal and Power Limited

The flagship integrated Steel manufacturing unit of BDG Group. A top-notch, reputed maker of high-quality, value-added steel products that are preferred in various projects across India.

LOTUS TMT Bars in BIS Grade

-

Fe-415/415D, Fe-500/500D, Fe-550/ 550D & Fe-600. Sizes: 8 to 32mm dia based on German Technology & design, which guarantees the specification of IS:1786/2008 & also the properties of various international standards.

WORLD CLASS TECHNOLOGY

Lotus TMT steels bars are based on latest technology & design which guarantees the properties to produce as per international standards. German BST 420S / 500S of DIM 488, British Gr.460 of Bs 4449-1988 Egyptian Standard 262/1988 Gr.36/52 and 40/60, Fe-514,500 & 550 of IS:1786/85’, JIS.G.3112 1975 SD30, 35, 40, 45 & 50 Swiss to par 550S of SIA 162, French Fe-E50 of NF A35-016. High strength reinforcement bar in grades of Fe-415, 500 and 550 as per IS:1786/2008 latest, that achive their properties by online computerised controlled thermo processing.

IN HOUSE FACILITY

To have control over every step of manufacturing, the group have installed the following modern facilities for producing more than 3.0 lakh MT per annum of steel:

-

500 TPD Sponge Iron Plant.

-

Sinter Plant.

-

6 nos. 24 pulse Steel Melting Induction Furnace.

-

LRF (Ladle Refining Furnace)to produce the desired quality of steel.

-

Continous 3 strands Billet Casting Machine with Automatic Level & speed Control System.

-

Completely automatic & computerised state of the art TMT & wire rod mills with “Turbo Quench” of Herbert Rothe, Germany certified most efficient quenching system & automatic extra-long walk-in cooling bed for self-tempering as per the above technology.

-

Ultra-Modern & Computerised Testing Laboratories with Spectrometer & also latest testing process.

-

We have the complete in-house facility for manufacturing of Billet in BIS 2830/2012 Grade. We are the first party to receive BIS approval for manufacturing of IS:2830 Grade billets in the Durgapur area.

Quality Assurances

-

Quality product, timely delivery & other services

-

Economy-cost savings in buying our products

-

Commitment – timely delivery at all places

-

Customer satisfaction

-

Safety for all

-

Customer Preference – at all times

Quality Control Facilities

-

Well-equipped chemical and physical laboratories for each section of the process.

-

Complete computerised testing system with the latest spectrometer.

-

Computerised system for quenching and self-tempering.

-

Ultramodern quality assurance and monitoring system.

-

Physical testing lab for 0.2% proof stress, tensile strength and elongation bend, re-bend, and pull-out test.

SPECIAL FEATURES

-

Earthquake Resistant (EQR)

For earthquake resistance, TMT bars structures need to have balanced stiffness, strength and ductility between its members, connections and supports. LOTUS TMT bars provide very high strengths with comparatively higher elongation values and better ductility, making more earthquake resistance.

-

Fire Resistant

The result of LOTUS TMT bars, have shown no loss of strength upto 500 degree C. At a temperature range of 550 degree C to 600 degree C, the yeild strength decreases by 20N/Sq mm only. That is why LOTUS TMT bars can be used easily in constructions prone to fire hazards.

-

Corrosion Resistant (CRS)

LOTUS TMT bars are more corrosion resistance than normal CTD bars. The fine layer of scale forms a protective layer, thereby preventing further corrosion, where as in CTD bars, this initial layer of scale falls down during twisting. Corrosion resistance can be further inproved as per customer needs, by altering material chemistry.

-

Strength and Elongation

Higher strength and better elongation is a unique feature of LOTUS TMT Bars. Designed to be much stronger than conventional bars, LOTUS build;s a safer and stronger concrete structure with laser quality of steel with a great savings over the market conventional requirement. LOTUS guarantees excellent Weldability, Ductility and Bendability. Tapered edge strength connections with little overlap. Due to its low carbon content, these bars can withstand better bending and re-bending without reduction in strength.

-

Superior Bonding with Cement

LOTUS TMT bars exhibit superior bonding with cement, ensuring strong and durable construction. The unique surface design of these bars enhances the adhesion with cement, providing a robust and long-lasting bond. This superior bonding capability contributes to the overall integrity and longevity of structures, making LOTUS TMT bars an excellent choice for all construction projects.

-

High Bendability & Flexibility

LOTUS TMT bars offer high bendability and flexibility, making them ideal for complex and intricate construction designs. Engineered for excellent bendability, these bars can withstand significant deformation without compromising strength. This flexibility allows for greater design freedom and structural resilience, ensuring that the bars can accommodate various construction needs and withstand dynamic stresses.

-

100% Rolled from Billets mfg. in Our Own Integrated Steel Plant

Every LOTUS TMT bar is rolled from billets produced in our own state-of-the-art integrated steel plant, ensuring the highest quality standards. By manufacturing our own billets, we guarantee that LOTUS TMT bars maintain superior consistency, purity, and strength. This in-house production process allows us to control every aspect of quality, providing our customers with reliable and top-grade construction materials.

| TMT Dia | Specific Weight gm/m | BIS Standard | Market Standard | LOTUS TMT Bar | ||||

|---|---|---|---|---|---|---|---|---|

| Tolerance gm/m | % Variation | Tolerance gm/m | % Variation | Tolerance gm/m | % Variation | Savings in terms (of Weight) | ||

| 6 mm | 222 | 206 to 237 | ±7 | 217 to 234 | +4 to -2 | 216 to 221 | -2.7 to – 6 | 5.50% |

| 8 mm | 395 | 367 to 423 | ± 7 | 387 to 410 | + 4 to -2 | 370 to 385 | – 2.5 to – 6 | 5.50% |

| 10 mm | 617 | 574 to 660 | ± 7 | 605 to 642 | + 4 to -2 | 580 to 600 | – 2.75 to – 6 | 5.40% |

| 12 mm | 888 | 844 to 932 | ± 5 | 870 to 924 | + 4 to -2 | 850 to 865 | – 2.6 to – 4.3 | 4.40% |

| 16 mm | 1580 | 1501 to 1659 | ± 5 | 1548 to 1643 | + 4 to -2 | 1515 to 1535 | – 2.85 to – 4 | 4.40% |

| 20 mm | 2470 | 2396 to 2544 | ± 3 | 2445 to 2519 | + 2 to -1 | 2400 to 2420 | – 2 to – 2.8 | 2.95% |

| 25 mm | 3850 | 3735 to 3965 | ± 3 | 3812 to 3927 | + 2 to -1 | 3750 to 3780 | – 1.8 to – 2.6 | 2.75% |

| 28 mm | 4830 | 4685 to 4875 | ± 3 | 4782 to 4927 | + 2 to -1 | 4700 to 4740 | – 1.8 to – 2.7 | 2.75% |

| 32 mm | 6310 | 6121 to 6499 | ± 3 | 6300 to 6500 | + 3 to -3 | 6200 to 6400 | – 1.7 to -1.4 | 1.60% |

| GRADE | Yield (min N/sq mn) | UTS (min N/sq mn) | Elongation (min %) | |||

|---|---|---|---|---|---|---|

| BIS | LOTUS | BIS | LOTUS | BIS | LOTUS | |

| Fe-415 | 415 | 450 | 485 | 550 | 14.5 | 18 |

| Fe-415D | 415 | 450 | 500 | 580 | 18 | 22 |

| Fe-500 | 500 | 530 | 545 | 600 | 12 | 16 |

| Fe-500D | 500 | 540 | 565 | 630 | 16 | 20 |

| Fe-550 | 550 | 580 | 585 | 650 | 10 | 14 |

| Fe-550D | 550 | 585 | 600 | 670 | 14.5 | 18 |

| Fe-600 | 600 | 620 | 660 | 700 | 10 | 14 |

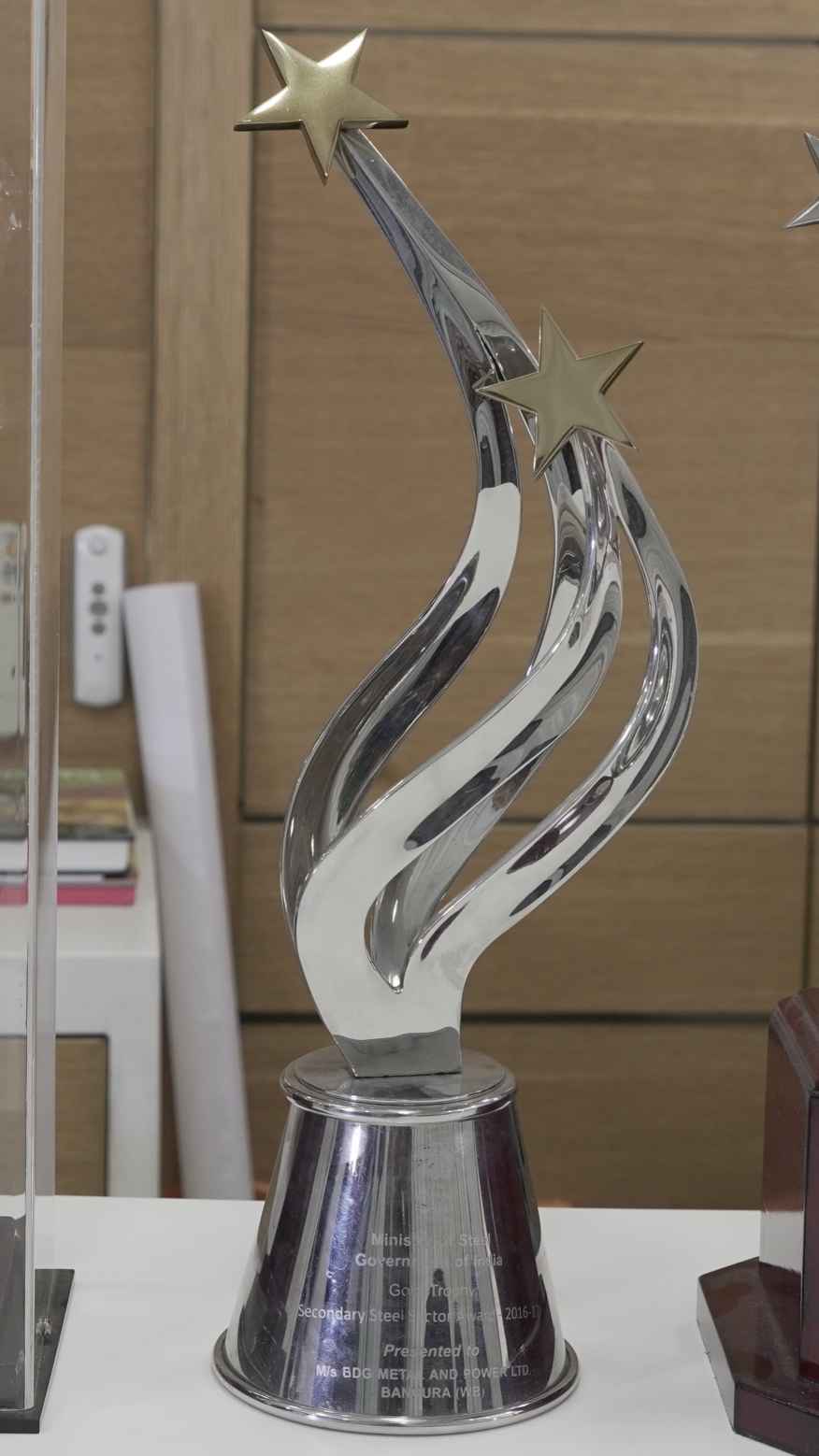

Awards & Appreciations