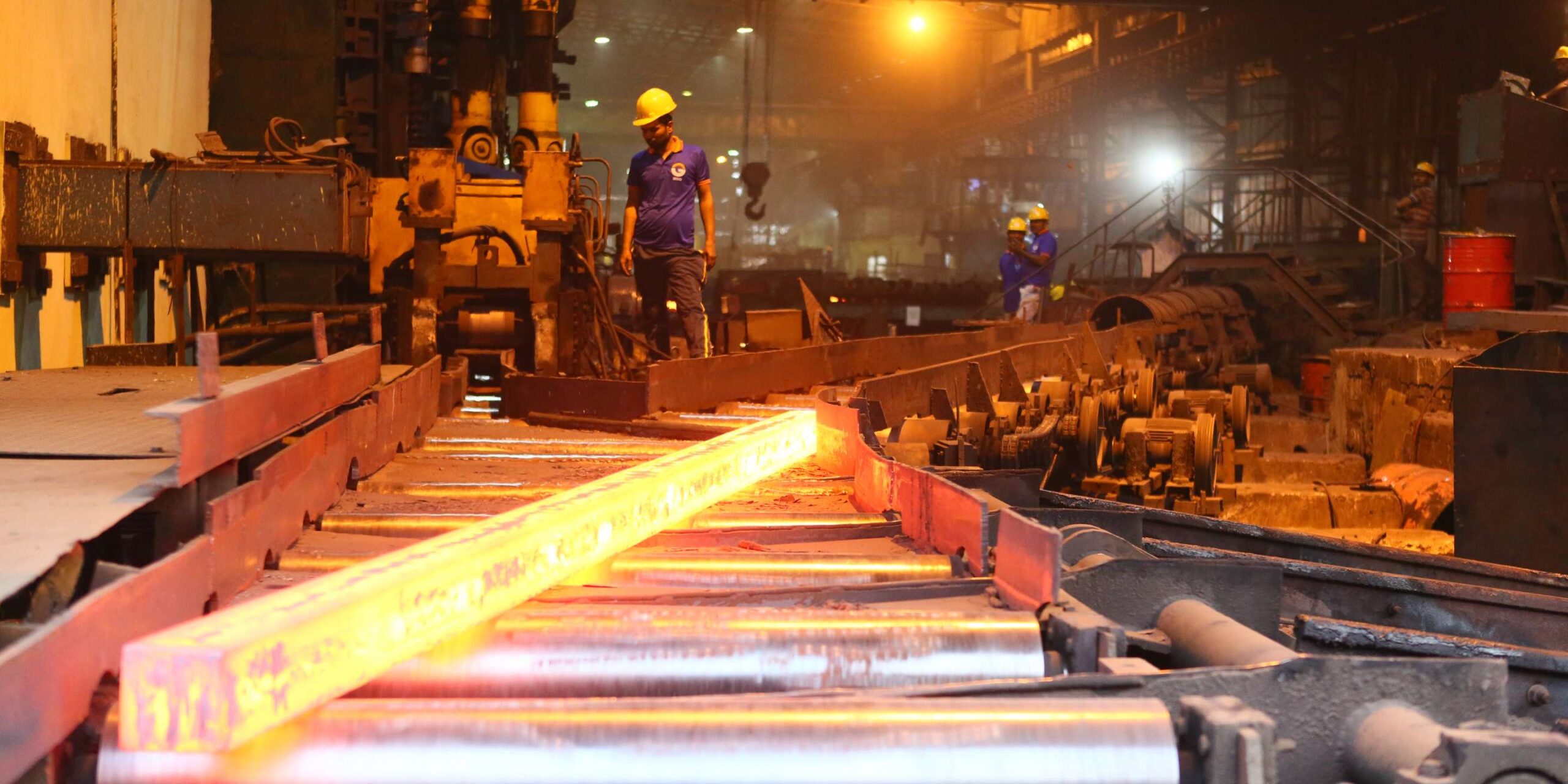

BILLETS

BDG Metal produces a wide range of continuously casted Billets in its Integrated Steel Plant. The state-of- art technology ensures international quality standards and ensures smooth and defect-free casting of billets. M.S. Billets are used for rolling of TMT Re-Bars of Fe 415/415D, Fe 500/500D, Fe 550/550D & Fe 600 Grade. The following are the specification of Billets available with BDG Metal & Power.

The following are the Special features of the Billets:

Excellent Surface Finish: The Billets produced are free from any surface. Magnetic particle test in order to identify any crack on the surface is done on a regular basis.

Dimensional Tolerance: Billets produced strictly in accordance to IS 2830 for dimensional tolerance.

No Internal Defects: The Billets produced are free from any internal defects. Defects such as piping blowholes and pinholes are identified and segregated by Sulphur Print Test.

| Description | As per IS 2830 | BDG Billets |

|---|---|---|

| Bend (max.) | 5 mm per meter | >= 5 mm per meter |

| Camber (max.) | 3mm per meter | >= 3 mm per meter |

| Length | 3 mt to 13 mt | 3 mt to 9 mt |

| Designation | %Carbon | %Manganese |

|---|---|---|

| C15 | 0.12-0.18+ | 0.30-0.60 |

| C18 | 0.15-0.21 | 0.30-0.60 |

| C20 | 0.17-0.23 | 0.30-0.60 |

| C15 MMn | 0.12-0.18 | 0.60-1.00 |

| C18 MMn | 0.15-0.21 | 0.60-1.00 |

| C20 MMn | 0.17-0.23 | 0.60-1.00 |

| C15 HMn | 0.12-0.18 | 1.00-1.80 |

| C18 HMn | 0.15-0.21 | 1.00-1.80 |

| C20 HMn | 0.17-0.23 | 1.00-1.80 |

Billets of different designations are manufactured in three different grades namely A, B, C having sulphur, phosphorous content (on ladle analysis) and carbon equivalent as follows

| Grade | Sulphur | Phosphorous | Carbon Equivalent (CE)1 |

|---|---|---|---|

| Max | Max | Max | |

| A | 0.050 | 0.050 | 0.42 |

| B | 0.045 | 0.045 | 0.41 |

| C | 0.040 | 0.040 | 0.39 |

-

Carbon equivalent based on ladle analysis = C + Mn/6 + (Cr+Mo+V)/5 + (Ni+Cu)/15

-

When steel is required in copper bearing quality, copper content is between 0.20 60 0.35 percent